Company News

Industry News

Exhibition

What is a spring-energized sealing ring, and what are the key features of spring-energized seals?

Release Time:

2022-12-14 14:09

Source:

Spring energy-storage sealing ring, an abbreviation for Spring Variseal (spring composite seal), is commonly known as a mechanical seal.

"Panse" itself is a transliteration of "composite sealing," so there's no need to add the word "sealing" after "Panse." However, if you prefer to follow conventional naming practices, adding those two words is also acceptable. Of course, in Chinese, it's even better to directly refer to it as "Spring-Energy-Sealing."

It is a U-shaped seal featuring a special Teflon lining and an embedded specialized spring. The unique design leverages the spring's inherent elasticity, combined with the pressure of the system fluid, to gently press the sealing lip against the metal surface, thereby achieving an exceptionally effective sealing performance. By incorporating various specialized springs, this solution effectively addresses the inherent elastic limitations of Teflon or other high-performance rubber and plastic materials. As a result, it has been developed to replace the vast majority of conventional seals used in static or dynamic applications—whether involving reciprocating or rotary motions. This innovative seal can operate across an impressive temperature range, from cryogenic conditions down to -200°C, up to 300°C; and it withstands pressures ranging from vacuum levels to ultra-high pressures as high as 1400 kg/cm². Additionally, its operational speed capability extends up to 20 m/s.

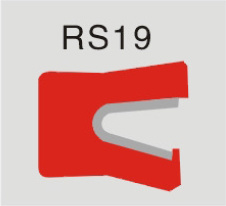

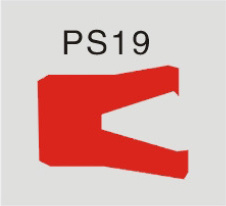

The structure of the Panseal is illustrated in the figure below, consisting of two distinct internal and external sections: the exterior is made of a special engineering plastic, while the interior features a stainless steel spring crafted from a specialized material.

Plastic and stainless steel materials vary depending on different operating conditions and working media. Generally, plastic materials include: pure PTFE, filled PTFE, ultra-high-molecular-weight polyethylene, polyimide, polyetheretherketone, and others. Stainless steel materials typically consist of SUS301, SUS304, SUS316, as well as Inconel®718, Elgiloy, and Hastelloy®C276, among others.

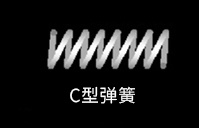

Spring configurations can also be selected as H(O)-type, V-type, C-type, or F-type depending on the specific operating conditions.

| Spring Type |

Spring Characteristics |

Application Features |

|

The V-shaped cantilever spring enables the PTFE sealing lip at the long arm end to press firmly against the sealing surface, providing moderate sealing force. It offers a broader range of spring loads and greater compensatory elasticity, ensuring stable spring performance with minimal deformation. This design allows for direct installation into standard O-ring grooves, and a backing ring can be added as needed. |

1. Shaft and Piston Seals for Reciprocating Motion 2. During static sealing, the sealing groove can accommodate larger tolerances and misalignment issues. 3. Dynamic seals can withstand temperatures up to 260°C and are suitable for rotating shaft sealing applications, achieving speeds of up to 4 m/s. |

|

H-type springs feature high spring rates, making them ideal for medium to high-pressure load applications. They deliver substantial spring force within a relatively small compression range, while ensuring even stress distribution across each coil. |

1. Static Shaft and Piston Sealing, Medium-to-High Pressure Sealing 2. For fast dynamic sealing applications, where speeds are below 3 m/s 3. Internal and External Pressure Face Sealing |

|

Type C springs are helical springs with a slanted cross-section, characterized by large deformation capacity and significant ability to compensate for dimensional deviations. |

1. Suitable for conditions with high friction requirements and low-pressure environments |

| Spring Material |

V-shaped |

Type C |

H(0) Type |

Type F |

| SUS301 |

Standard |

|

There is |

Standard |

| SUS304 |

|

|

There is |

|

| SUS316 |

There is |

There is |

There is |

|

| Hastelloy@C276 |

There is |

There is |

There is |

|

| Incone@718 |

There is |

|

|

|

| Elgiloy@ |

|

|

There is |

|

| 17-7 PH |

|

|

Standard |

|

The external plastic sleeve comes into contact with the two surfaces to be sealed, providing the sealing function. Therefore, it requires a low coefficient of friction, high strength, excellent wear resistance, and resistance to the working medium as well as to high or low temperatures in the operating environment.

The internal stainless steel spring provides pressure to the external sealing sleeve, ensuring that the sleeve remains tightly pressed against the sealing contact surface at all times, effectively preventing leakage—especially when the internal pressure is low, even at zero or negative pressure. In such cases, the spring becomes the sole source of sealing pressure. The requirements for the spring itself are relatively straightforward: it must withstand extreme environmental temperatures, exhibit excellent corrosion resistance, and maintain a consistently stable elastic force. While these specifications may seem few in number, achieving them is not easy. Therefore, high standards are placed on the spring's material, manufacturing process, and overall shape.