Company News

Industry News

Exhibition

85 Technical Requirements for CAD Mechanical Drawings

Release Time:

2022-03-20 16:08

Source:

Comprehensive Technical Requirements for Mechanical Drawings

1. Remove oxide scale from the parts.

2. The machined surfaces of parts shall not exhibit defects such as scratches or abrasions that could damage the part surfaces.

3. Remove burrs and flash.

4. After tempering treatment, HRC 50–55.

5. The parts undergo high-frequency quenching, followed by tempering at 350–370°C, achieving a hardness of HRC 40–45.

6. Carburized depth: 0.3 mm.

7. Perform high-temperature aging treatment.

8. Unspecified geometric tolerances shall comply with the requirements of GB1184-80.

9. Unspecified dimension lengths are permitted to have an allowable deviation of ±0.5 mm.

10. The tolerance zone of the casting is symmetrically arranged with respect to the basic dimension configuration of the blank casting.

11. Unspecified fillet radius R5.

12. All unannotated chamfers are 2 × 45°.

13. Chamfer sharp corners.

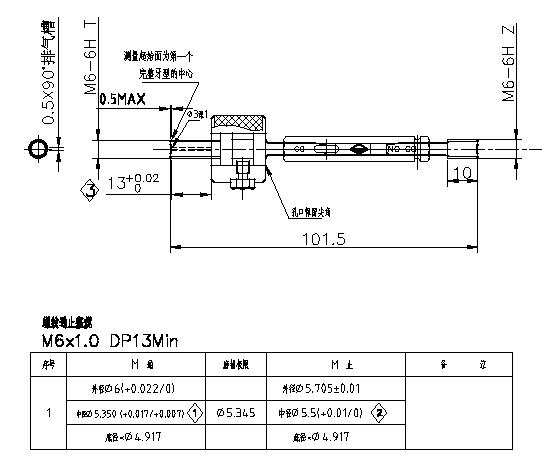

Thread Depth Go/No-Go Plug Gauge

14. All seals must be thoroughly soaked in oil before assembly.

15. When installing rolling bearings, hot fitting using oil heating is permitted, provided that the oil temperature does not exceed 100°C.

20. After gear assembly, the contact spots and backlash on the tooth surfaces shall comply with the provisions of GB 10095 and GB 11365.

21. Sealing fillers or sealants may be used during the assembly of the hydraulic system, provided that they are prevented from entering the system.

22. All parts and components entering the assembly process (including purchased and outsourced items) must bear a certificate of conformity issued by the inspection department before assembly can proceed.

23. Before assembly, all parts must be thoroughly cleaned and free of burrs, flash, scale, rust, chips, oil stains, coloring agents, and dust.

24. Prior to assembly, the key mating dimensions of components and parts should be rechecked, particularly those for interference fits as well as their associated precision requirements.

25. During the assembly process, parts must not be subjected to impacts, collisions, scratches, or rusting.

26. When tightening screws, bolts, and nuts, it is strictly prohibited to strike them or use improper screwdrivers and wrenches. After tightening, the screw slots, nut surfaces, and the heads of screws and bolts must remain undamaged.

27. Fasteners requiring specified tightening torque must be tightened using a torque wrench according to the prescribed torque value.

28. When multiple screws (bolts) are used to fasten the same part, each screw (bolt) should be tightened in a crosswise, symmetrical, gradual, and uniform manner.

29. When assembling the tapered pins, a color check should be performed against the holes to ensure that the contact rate is no less than 60% of the mating length and is evenly distributed.

30. The flat key should be in uniform contact with both side faces of the keyway on the shaft, and there shall be no gaps between the mating surfaces.

31. The number of tooth surfaces in simultaneous contact during spline assembly shall be no less than 2/3, and the contact rate in both the length and height directions of the key teeth must not fall below 50%.

32. After assembly, the sliding-fit key (or spline) should move smoothly and freely without any uneven tightness or looseness between mating parts.

33. Excess adhesive should be removed after bonding to prevent overflow.

34. The outer ring of the bearing must not be jammed in the semicircular holes of the open-type bearing housing and bearing cover.

35. The outer ring of the bearing should have good contact with the semi-circular holes in the open-type bearing housing and bearing cover. When checked by color application, uniform contact should be achieved within a range of 120° symmetrically about the centerline for the bearing housing and 90° symmetrically about the centerline for the bearing cover. Additionally, when using feeler gauges within these specified ranges, a 0.03 mm gauge must not be able to penetrate into one-third of the outer ring's width.

36. After assembly, the outer race of the bearing should make uniform contact with the end face of the locating bearing cap.

37. After installation, the rolling bearing should rotate smoothly and freely by hand.

38. The mating surfaces of the upper and lower bearing shells must be tightly fitted, with no gap detectable when checked using a 0.05 mm feeler gauge.

39. When securing the bearing bushing with locating pins, ensure that the bushing face and end face are flush with the corresponding bearing bore's opening and end surfaces before drilling, reaming, and fitting the pins. Once installed, the pins must remain firmly in place without any looseness.

40. The bearing housing of the spherical bearing should be in uniform contact with the bearing seat, and when checked using the coloring method, the contact area should not be less than 70%.

41. When the surface of the alloy bearing liner turns yellow, it must not be used. Within the specified contact angle, no core separation is allowed; outside the contact angle, the area of core separation shall not exceed 10% of the total non-contact area.

42. The reference end face of the gear (worm wheel) shall be tightly fitted against the shaft shoulder (or the end face of the locating sleeve), with no gap detectable when checked using a 0.05 mm feeler gauge. Additionally, the perpendicularity requirement between the gear's reference end face and the axis must be strictly maintained.

43. The mating surface between the gearbox and the cover should have good contact.

44. Before assembly, thoroughly inspect and remove any sharp edges, burrs, and foreign objects left over from the machining process. Ensure that the sealing components are inserted without being scratched or damaged.

45. Casting surfaces shall not exhibit cold shuts, cracks, shrinkage cavities, or any penetrating defects, as well as severe imperfections such as misruns or mechanical damage.

57. The surface of the casting shall be smooth, and any浇口, burrs, sand adhesion, or other imperfections must be thoroughly removed.

47. Cast characters and markings on the non-machined surfaces of castings shall be clearly legible, with their positions and fonts conforming to the requirements specified in the drawings.

48. The roughness of non-machined surfaces on castings, for sand casting (R), shall not exceed 50 μm.

49. Castings shall be free from risers, sprues, and flash. Residual risers on non-machined surfaces must be carefully chipped off and smoothly ground to meet the required surface quality standards.

50. The molding sand, core sand, and core supports on the castings shall be thoroughly removed.

51. For castings with inclined sections, the dimensional tolerance zones shall be symmetrically arranged along the inclined surfaces.

52. The molding sand, core sand, core supports, excess metal, adhering sand, and other residues on the casting shall be scraped, ground smooth, and thoroughly cleaned.

53. Misalignment, casting offsets of bosses, and other defects should be corrected to ensure smooth transitions, thereby guaranteeing the quality of the appearance.

54. Wrinkles on the non-machined surfaces of castings, with a depth less than 2 mm, shall be spaced more than 100 mm apart.

55. Non-machined surfaces of machine product castings shall all undergo shot blasting or tumbling treatment to meet the cleanliness requirement of Sa2 1/2 grade.

56. The casting must undergo water toughening treatment.

57. The surface of the casting shall be smooth, and any浇口, burrs, sand adhesion, or other imperfections must be thoroughly removed.

58. Castings shall not contain any casting defects such as cold shuts, cracks, or porosity that may compromise their serviceability.

59. All steel components requiring painting must have their surfaces thoroughly cleaned of rust, scale, grease, dust, dirt, salt, and other contaminants before applying paint.

60. Before rust removal, first use organic solvents, alkaline solutions, emulsifiers, steam, and other agents to remove oil and dirt from the surface of steel components.

61. The time interval between the shot blasting or manual rust removal of surfaces to be coated and the application of primer shall not exceed 6 hours.

62. Surfaces of riveted components that come into contact with each other must be coated with an anti-rust paint of 30–40 μm thickness before assembly. Overlapping edges should be sealed using paint, putty, or adhesive. Any primer damaged during machining or welding must be reapplied.

63. Before assembly, all tubes shall have their pipe ends deburred, trimmed of burrs, and chamfered. Use compressed air or other suitable methods to thoroughly remove any debris and loose rust adhering to the inner walls of the tubes.

64. Prior to assembly, all steel pipes (including pre-fabricated pipelines) must undergo degreasing, pickling, neutralization, water rinsing, and rust-proofing treatments.

65. During assembly, all threaded connections such as pipe clamps, supports, flanges, and joints must be securely tightened to prevent loosening.

66. All prefabricated and completed pipe welding sections shall undergo pressure testing.

67. When replacing or transferring piping, the pipe connection points must be sealed with adhesive tape or plastic caps to prevent any debris from entering, and labeled accordingly.

68. Before welding, defects must be thoroughly removed, and the bevel surface should be ground smooth and rounded without any sharp corners remaining.

69. Depending on the type of defects found in the cast steel components, defects in the weld zone can be removed using methods such as chipping, grinding, carbon arc gouging, gas cutting, or mechanical machining.

70. Any adhering sand, oil, water, rust, or other contaminants within 20 mm around the weld area and bevel must be thoroughly removed.

71. Throughout the entire welding process, the temperature of the preheating zone for cast steel components must not fall below 350°C.

72. Whenever conditions permit, weld in the horizontal position whenever possible.

73. During repair welding, the electrode should not be swung horizontally with excessive amplitude.

74. When surfacing welds are applied to the surface of steel castings, the overlap between weld passes shall not be less than 1/3 of the weld pass width. The weld metal must be fully filled, with no burn-through, cracks, or obvious nodules on the welding surface. The weld appearance should be aesthetically pleasing, free from defects such as undercutting, slag inclusion, porosity, cracking, and spatter; additionally, the weld bead pattern must be uniform.

The sprue and riser of the ingot should have sufficient material removal allowance to ensure that the forging is free from shrinkage cavities and severe misruns.

76. Forgings shall be formed on forging presses with sufficient capacity to ensure thorough penetration throughout the forging.

77. Forgings shall not exhibit visible cracks, laps, or other surface defects that could affect their usability. Localized defects may be removed, provided the removal depth does not exceed 75% of the machining allowance. Additionally, defects on the non-machined surfaces of the forgings must be thoroughly cleaned and smoothly blended to ensure proper transition.

78. Forgings shall not contain white spots, internal cracks, or residual shrinkage cavities.

81. After finishing, the machined parts must not be placed directly on the ground; instead, necessary support and protective measures should be implemented. The machined surfaces must remain free from rust, corrosion, as well as any defects such as dents, scratches, or other marks that could compromise performance, service life, or appearance.

82. The surface after roll finishing must not exhibit any peeling after rolling.

83. Parts that have undergone the final heat treatment process should not have oxide scale on their surfaces. Additionally, machined mating surfaces and toothed surfaces must remain free from annealing marks.

84. The machined threaded surfaces shall not have defects such as scale, impact marks, cross-threading, or burrs.

85. The phenomenon of bluing and discoloration.